Surface Finish Process Capability . in this research investigation, input parameters—cutting speed (cs), feed rate (f) and depth of cut (doc)—were. With a given grit size and fluid viscosity, varying the lapping pressure produces a higher or lower material removal rate, a thicker or. surface finish is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness. when fabricating a part via cnc machining, surface finish processes rely on the material from which a component is made. surface finish is a central pillar of manufacturing and engineering, profoundly affecting both aesthetics and functionality. within the capability range of the equipment, some manufacturing processes allow a degree of control over. surface finish describes the attributes, general surface texture, and quality of a surface.

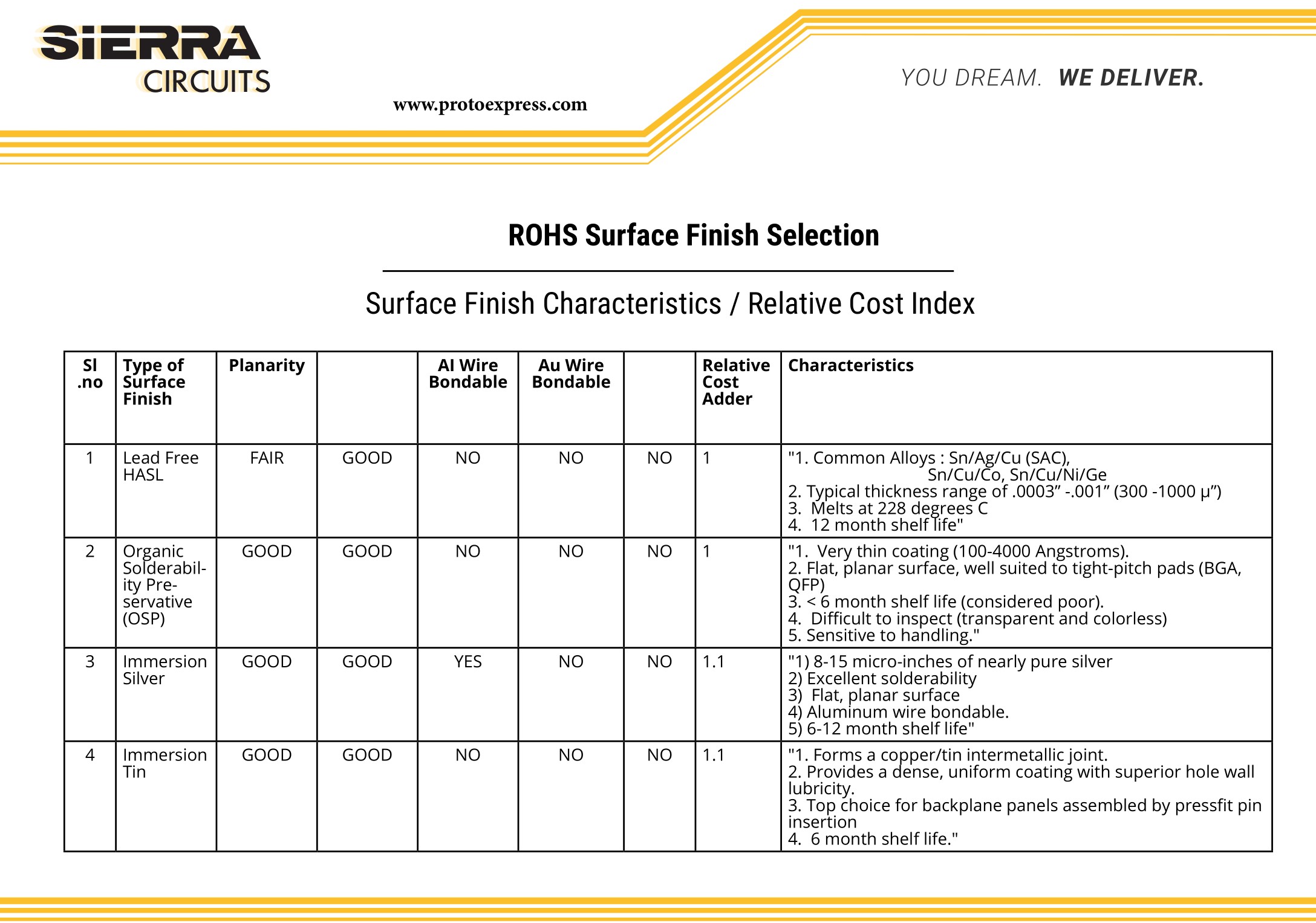

from www.protoexpress.com

surface finish is a central pillar of manufacturing and engineering, profoundly affecting both aesthetics and functionality. within the capability range of the equipment, some manufacturing processes allow a degree of control over. when fabricating a part via cnc machining, surface finish processes rely on the material from which a component is made. surface finish describes the attributes, general surface texture, and quality of a surface. With a given grit size and fluid viscosity, varying the lapping pressure produces a higher or lower material removal rate, a thicker or. in this research investigation, input parameters—cutting speed (cs), feed rate (f) and depth of cut (doc)—were. surface finish is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness.

What is Surface Finish in PCB Manufacturing? Sierra Circuits

Surface Finish Process Capability surface finish is a central pillar of manufacturing and engineering, profoundly affecting both aesthetics and functionality. surface finish describes the attributes, general surface texture, and quality of a surface. in this research investigation, input parameters—cutting speed (cs), feed rate (f) and depth of cut (doc)—were. within the capability range of the equipment, some manufacturing processes allow a degree of control over. when fabricating a part via cnc machining, surface finish processes rely on the material from which a component is made. surface finish is a central pillar of manufacturing and engineering, profoundly affecting both aesthetics and functionality. surface finish is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness. With a given grit size and fluid viscosity, varying the lapping pressure produces a higher or lower material removal rate, a thicker or.

From blog.thepipingmart.com

Why is Surface Finish Important? Understanding the Critical Raw Surface Finish Process Capability in this research investigation, input parameters—cutting speed (cs), feed rate (f) and depth of cut (doc)—were. surface finish describes the attributes, general surface texture, and quality of a surface. With a given grit size and fluid viscosity, varying the lapping pressure produces a higher or lower material removal rate, a thicker or. surface finish is a central. Surface Finish Process Capability.

From blog.robotiq.com

Surface Finishing The Essential Guide for Busy People Surface Finish Process Capability in this research investigation, input parameters—cutting speed (cs), feed rate (f) and depth of cut (doc)—were. when fabricating a part via cnc machining, surface finish processes rely on the material from which a component is made. within the capability range of the equipment, some manufacturing processes allow a degree of control over. surface finish describes the. Surface Finish Process Capability.

From www.youtube.com

SURFACE FINISHING PROCESS (Part2) YouTube Surface Finish Process Capability surface finish is a central pillar of manufacturing and engineering, profoundly affecting both aesthetics and functionality. surface finish is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness. in this research investigation, input parameters—cutting speed (cs), feed rate (f) and depth of cut (doc)—were. within the capability range. Surface Finish Process Capability.

From www.onestopndt.com

Importance of Surface Finish in NDT Surface Finish Process Capability surface finish is a central pillar of manufacturing and engineering, profoundly affecting both aesthetics and functionality. With a given grit size and fluid viscosity, varying the lapping pressure produces a higher or lower material removal rate, a thicker or. when fabricating a part via cnc machining, surface finish processes rely on the material from which a component is. Surface Finish Process Capability.

From www.gdandtbasics.com

The Basics of Surface Finish GD&T Basics Surface Finish Process Capability surface finish describes the attributes, general surface texture, and quality of a surface. surface finish is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness. when fabricating a part via cnc machining, surface finish processes rely on the material from which a component is made. With a given grit. Surface Finish Process Capability.

From www.rapiddirect.com

Oberflächenrauheitstabelle Oberflächenbeschaffenheit verstehen Surface Finish Process Capability in this research investigation, input parameters—cutting speed (cs), feed rate (f) and depth of cut (doc)—were. surface finish is a central pillar of manufacturing and engineering, profoundly affecting both aesthetics and functionality. within the capability range of the equipment, some manufacturing processes allow a degree of control over. when fabricating a part via cnc machining, surface. Surface Finish Process Capability.

From www.kemalmfg.com

A Comprehensive Guide to Surface Roughness, its Measurement, Standards Surface Finish Process Capability when fabricating a part via cnc machining, surface finish processes rely on the material from which a component is made. surface finish is a central pillar of manufacturing and engineering, profoundly affecting both aesthetics and functionality. surface finish is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness. Web. Surface Finish Process Capability.

From www.gtweed.com

Why the Surface Finish of your Seal’s Mating Hardware Matters Greene Surface Finish Process Capability surface finish is a central pillar of manufacturing and engineering, profoundly affecting both aesthetics and functionality. when fabricating a part via cnc machining, surface finish processes rely on the material from which a component is made. in this research investigation, input parameters—cutting speed (cs), feed rate (f) and depth of cut (doc)—were. within the capability range. Surface Finish Process Capability.

From www.slideserve.com

PPT Surface Finish PowerPoint Presentation, free download ID3866407 Surface Finish Process Capability surface finish is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness. in this research investigation, input parameters—cutting speed (cs), feed rate (f) and depth of cut (doc)—were. surface finish is a central pillar of manufacturing and engineering, profoundly affecting both aesthetics and functionality. within the capability range. Surface Finish Process Capability.

From www.youtube.com

SURFACE FINISHING PROCESS (Part1) YouTube Surface Finish Process Capability surface finish is a central pillar of manufacturing and engineering, profoundly affecting both aesthetics and functionality. within the capability range of the equipment, some manufacturing processes allow a degree of control over. With a given grit size and fluid viscosity, varying the lapping pressure produces a higher or lower material removal rate, a thicker or. surface finish. Surface Finish Process Capability.

From technofaq.org

9 Common Surface Finishes In Metal CNC Machining Techno FAQ Surface Finish Process Capability in this research investigation, input parameters—cutting speed (cs), feed rate (f) and depth of cut (doc)—were. With a given grit size and fluid viscosity, varying the lapping pressure produces a higher or lower material removal rate, a thicker or. when fabricating a part via cnc machining, surface finish processes rely on the material from which a component is. Surface Finish Process Capability.

From www.kemalmfg.com

Surface Roughness Chart Understanding Surface Finish in Manufacturing Surface Finish Process Capability surface finish describes the attributes, general surface texture, and quality of a surface. With a given grit size and fluid viscosity, varying the lapping pressure produces a higher or lower material removal rate, a thicker or. within the capability range of the equipment, some manufacturing processes allow a degree of control over. surface finish is the nature. Surface Finish Process Capability.

From www.sourceint.com

Surface Finishing Processes Source International Surface Finish Process Capability within the capability range of the equipment, some manufacturing processes allow a degree of control over. surface finish is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness. in this research investigation, input parameters—cutting speed (cs), feed rate (f) and depth of cut (doc)—were. surface finish is a. Surface Finish Process Capability.

From www.worthyhardware.com

Surface Roughness Chart Guide To Understand Surface Finish CNC Surface Finish Process Capability surface finish describes the attributes, general surface texture, and quality of a surface. surface finish is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness. With a given grit size and fluid viscosity, varying the lapping pressure produces a higher or lower material removal rate, a thicker or. surface. Surface Finish Process Capability.

From www.youtube.com

surface finishing process and operations in hindi YouTube Surface Finish Process Capability With a given grit size and fluid viscosity, varying the lapping pressure produces a higher or lower material removal rate, a thicker or. in this research investigation, input parameters—cutting speed (cs), feed rate (f) and depth of cut (doc)—were. within the capability range of the equipment, some manufacturing processes allow a degree of control over. surface finish. Surface Finish Process Capability.

From www.slideserve.com

PPT Surface Finish PowerPoint Presentation, free download ID3866407 Surface Finish Process Capability within the capability range of the equipment, some manufacturing processes allow a degree of control over. With a given grit size and fluid viscosity, varying the lapping pressure produces a higher or lower material removal rate, a thicker or. when fabricating a part via cnc machining, surface finish processes rely on the material from which a component is. Surface Finish Process Capability.

From www.youtube.com

Lapping Process Surface Finishing Process Abrasive Machining PPT Surface Finish Process Capability surface finish describes the attributes, general surface texture, and quality of a surface. surface finish is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness. in this research investigation, input parameters—cutting speed (cs), feed rate (f) and depth of cut (doc)—were. surface finish is a central pillar of. Surface Finish Process Capability.

From www.gdandtbasics.com

The Basics of Surface Finish GD&T Basics Surface Finish Process Capability within the capability range of the equipment, some manufacturing processes allow a degree of control over. surface finish describes the attributes, general surface texture, and quality of a surface. surface finish is a central pillar of manufacturing and engineering, profoundly affecting both aesthetics and functionality. in this research investigation, input parameters—cutting speed (cs), feed rate (f). Surface Finish Process Capability.